This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

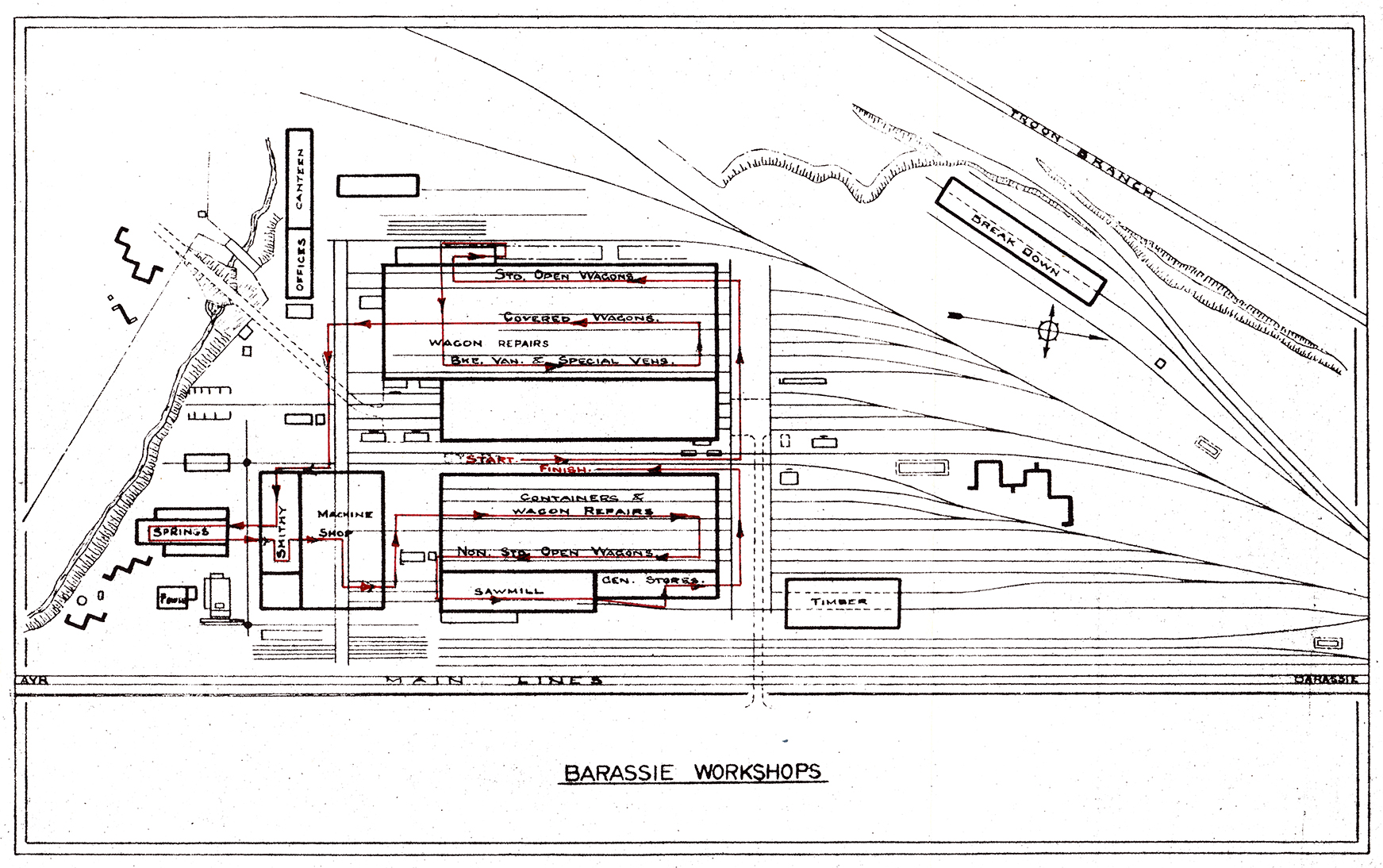

The Workshops were built in 1901 by the Glasgow and South Western Railway for the repair of carriages and wagons , and cover an area of 22 acres, of which six are covered by buildings.

After the amalgamation of the railways in 1923 it was decided to transfer all carriage repairs to St. Rollox and retain Barassie as a main factory for wagon repairs in the Northern Division. This change-over took place in 1929.

With the cessation of the painting of wagons as a wartime measure, the Paint Shop was used as an Aircraft Repair Depot and is at present being vacated by M.A.P.

The staff employed at the present time is :-

| Male | Female | Total |

|---|---|---|

| 492 | 65 | 557 |

The Shops have recently been modernised to deal with repairs to:-

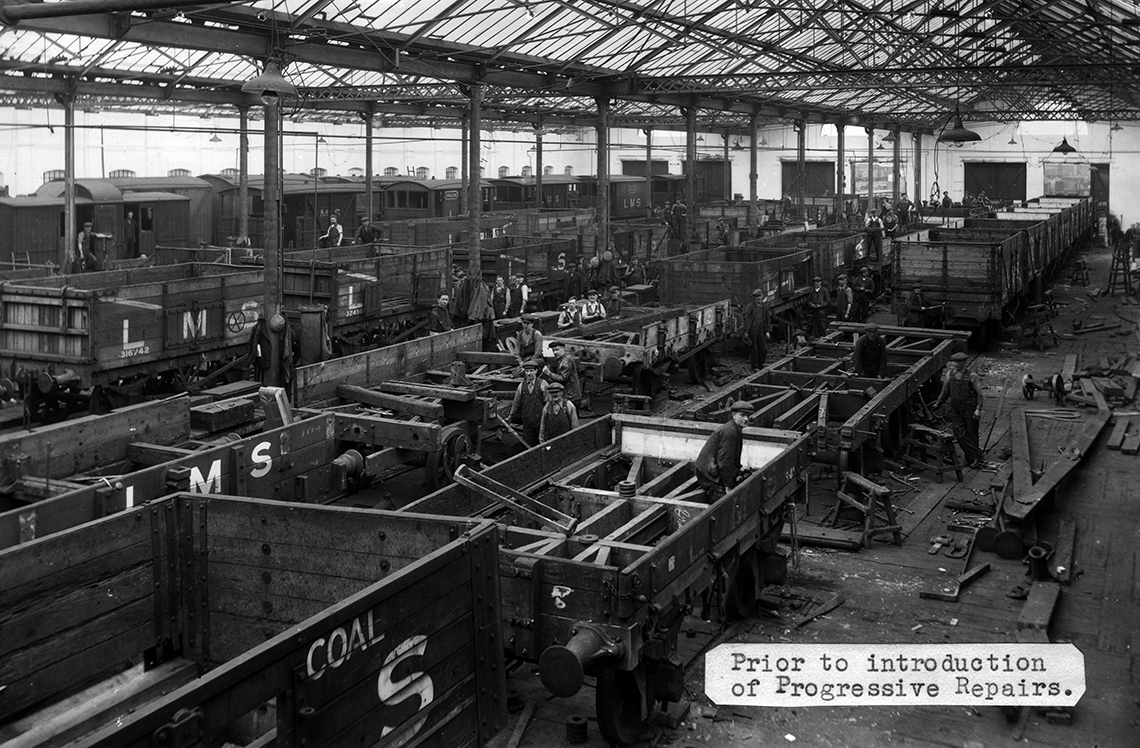

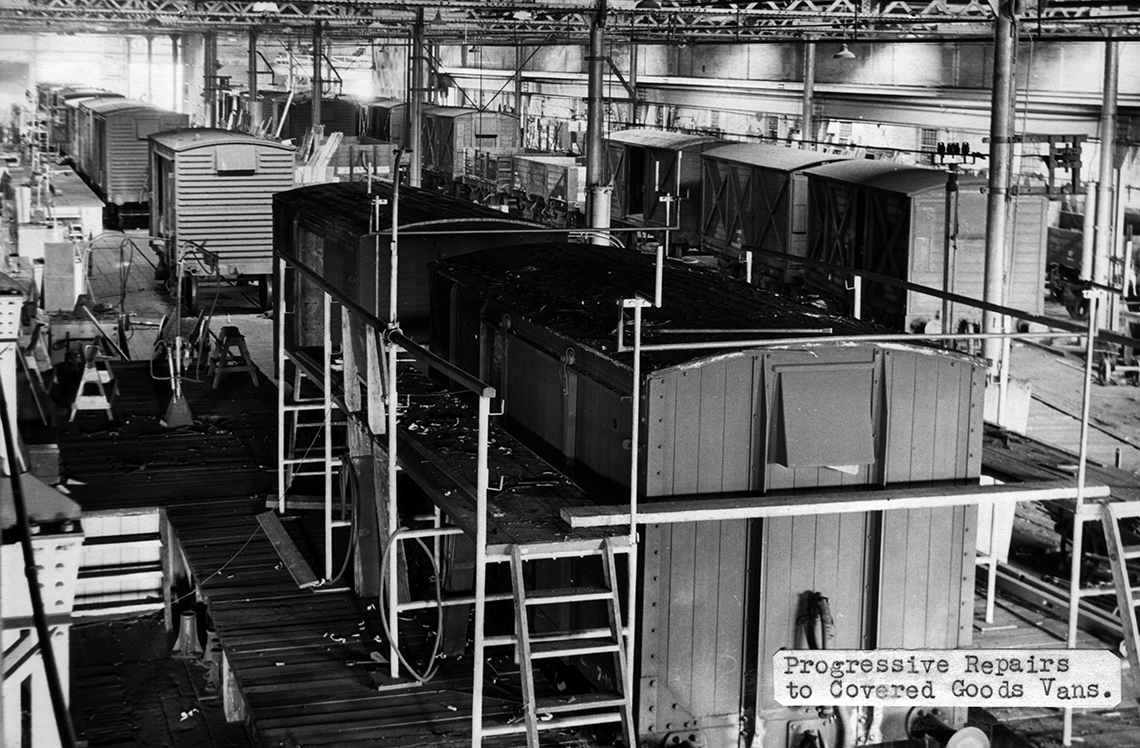

The unrepaired wagons entering these three sections pass through "staged" repairs, the sequence of operations being progressive, i.e.

These three lay-outs are equipped with pneumatic and high frequency electric tools and are designed to handle a total of 150 wagons per week.

Lifting is carried out by overhead crane, except in the case of Covered Stock, which lay-out incorporates a specially designed lifting unit.

A feature of these lay-outs is the provision of circular saws for converting to re-usable items the timber recovered from wagons under repair.

After completion of repairs the wagons pass through Spray Painting Sections.

Goods Brakevans and Special Class Stock are presently dealt with in the Special Wagon Shop, which is equipped with two 15-ton overhead electric cranes, and repairs are carried out on progressive lines.

One Bay also deals with repairs to miscellaneous vehicles and Containers, lifting in these cases being done with an overhead electric crane specially constructed to deal with vehicles of varying lengths.

This Shop is mainly engaged on the conversion of second-hand and scrap timber for re-use in the Wagon Shops.

In the Firelighter Shop adjacent, scrap timber produced in the factory is converted into firelighters for the Motive Power Department.

This Shop is laid out for :-

A portion of the Shop which has been used recently for aircraft repairs, is being reorganised.

The five wheel lathes and the journal grinding machine situated in various parts of the Workshops are included in the activities of the Machine Shop, and adjacent to the Wheel Lathe Shop is a recently installed automatic metallic arc welding machine for re-building worn tyre flanges.

This Shop, in which the reconditioning of laminated springs is carried out, is in course of modernisation. incorporating gas producer plant to eliminate the use of solid fuel in the furnaces; temperature controlled gas producer furnaces, spring buckling press, etc.

Half of the original Smithy has been set out as an Electric Welding Bay and will contain welding booths and equipment for the repair of reclaimed ferrous components.

The remainder of the Shop has recently been reorganised, two new furnaces being provided, heated with producer gas from the plant in the Spring Shop.

The Shop also contains the necessary steam hammers, Smiths' hearths, etc. to deal with the reconditioning of wagon iron work.

Condemned wagons are dismantled in the Breakdown Shed, which is laid out for easy loading of scrap material direct from the vehicle being broken up and easy transport of material for reconditioning in the sawmill and Machine Shops.

Electric current is supplied by the Ayrshire Electricity Board at 11,000 volts A.C. and is transformed

and converted to 440 volts and 230 volts D.C. for machine tools and cranes, and 250 volts A.C. for light mg.

| Consumption for 1944 | Units |

| Power | 473,900 |

| Lighting | 203,100 |

| Total | 677,000 |

| Price per unit | 0.89d. |

| Total cost | £2,510 |

Gas

| Consumption for 1944 |

| 204,000 cu.ft. at a cost of &37. |

Water

| Consumption for 1944 |

| 10,837,400 galls. at a cost of &356. |

The Canteen is modern, having been largely equipped by M.A.P. during the time "Spitfire" repairs were being undertaken. Presently there are 170 main meals and 120 subsidiary meals served daily, in addition to which 600 cups of tea are taken.

There is a Mobile Canteen Service and during the two turns per day approximately 900 cups of tea with

some light food are served.

Site contents Copyright © LMS Society, 2026

February 2nd, 2026

Site contents Copyright © LMS Society, 2026