This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

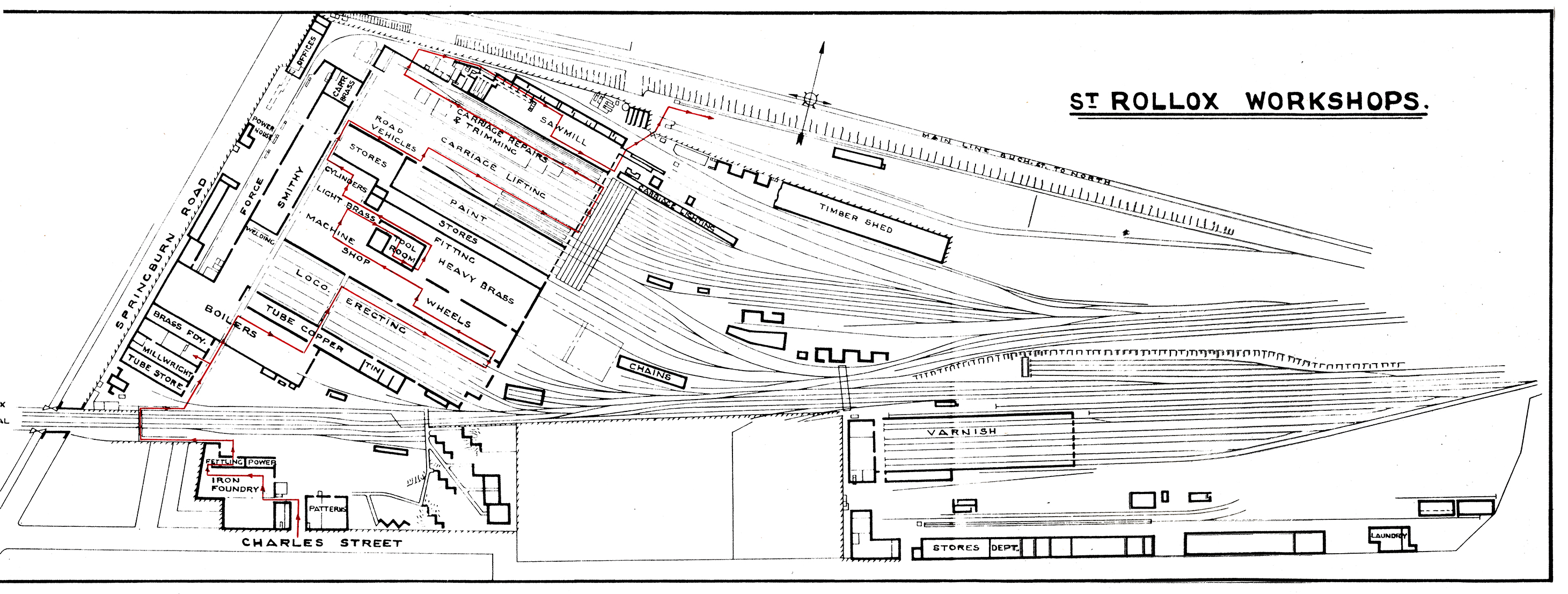

The Workshops occupy the site of what formed the original terminus of Glasgow's earliest railway, the Garnkirk Line, the first Workshops having been built in 1856. The Works were rebuilt in 1882-84 for the construction and repair of the Caledonian Railway Company's locomotives, carriages and wagons and for mechanical work of various kinds in connection with the Company's Docks, Canals, Signal, Telegraph and other departments of the service. The only addition which has been made to the buildings since then was an extension to the Boiler Shop. An adjacent Pipe Foundry was purchased in 1916 and the Iron Foundry and Pattern Shop were transferred to these buildings.

In the reorganisation of the Workshops on the Northern Division after Amalgamation, all Heavy Repairs to Locomotives and carriages were concentrated at St. Rollox and Heavy Repairs to wagons transferred to Barassie. The part of the Workshops which had previously been occupied as a Wagon Shop was utilised to increase the Locomotive Machine and Fitting Shops and the Carriage Repair Shops and to provide a General Store for locomotive and carriage components under the control of the Divisional Storekeeper. These changes commenced in November, 1927, with the closing of the Locomotive Repair Shops at Perth, and were completed in 1930.

The Workshops cover an area of 31½ acres, of which 15½ acres are covered by buildings.

The total staff employed at the present time is made up as follows :-

| Section | Male | Female | Total |

|---|---|---|---|

| Locomotive | 1,857 | 198 | 2,055 |

| Carriage | 939 | 59 | 998 |

| 2,796 | 257 | 3,053 |

The average weekly outputs are :-

| Class or repair | Average No. weekly. |

|---|---|

| Locomotives | |

| Heavy | 7 |

| Light | 5 |

| Running | 2 |

| Total | 14 |

| Carriages | |

| Heavy | 36 |

| Light | 4 |

| Other | 20 |

| Total | 60 |

| Road Vehicles | |

| Heavy | 14 |

| Light | 2 |

| Total | 16 |

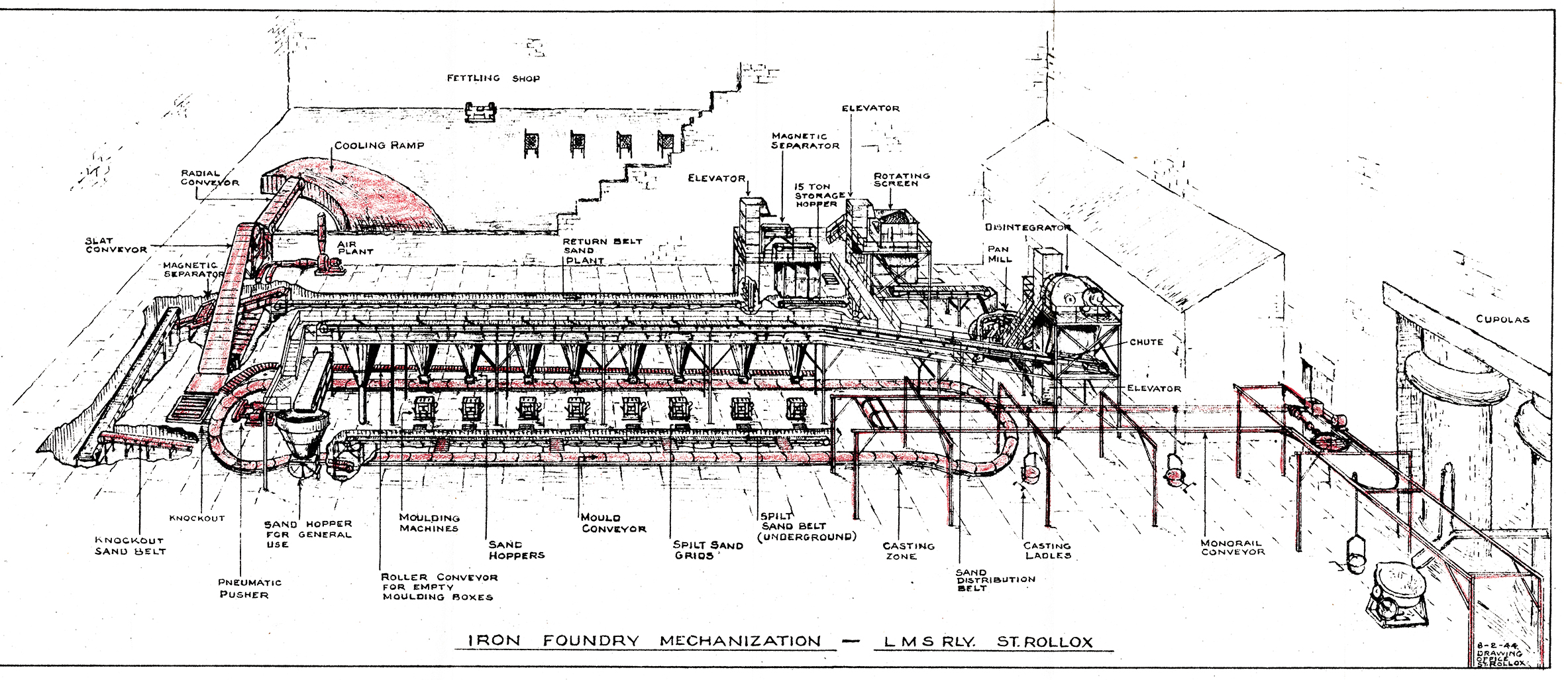

The Iron Foundry, which produces all the iron castings required for locomotives, carriages and wagons and also signal work in the Northern Division, has an output of 160 tons per week.

A sand mixing and distributing plant for the moulding machines was installed in 1936.

The complete mechanisation of the Machine Moulding Section of the Foundry has recently been completed by Messrs. Foundry Equipment Ltd. This equipment includes a casting conveyor which takes the moulds from the machines to a casting station, where the metal is poured from a ladle carried on an overhead runway from the cupola. The moulds then continue on the conveyor to an automatic knockout, where the casting is removed from the moulding box and transported on conveyor to the Fettling Shop. The moulding box is returned to the machines by overhead conveyor fitted with a cooling chamber, while the sand from the box drops on to the sand conveyor belt of the sand mixing plant and is returned to the sand hopper for reconditioning. There are six moulding machines in this section. Molten metal is supplied by two cupolas.

As the Factory Act Regulations prohibit the use of sand blasting of castings, a Tilghman Shot Wheelabrator Airless Tumblast machine has been installed. The castings are cleaned by means of chilled iron shot impelled on to them in a rotating conveyor of the apron type.

The Boiler Shop is equipped for the general overhaul of six boilers and the construction of one new boiler weekly; repairs to stationary boilers and general plating work.

There is a considerable increase in the amount of copper welding now carried out on boilers, resulting in the saving of material.

The Boiler Building Programme for 1945 is 40 boilers.

The Tube Shop contains a special layout for the repair of boiler tubes. This equipment consists of reeling, cutting, butt welding, bulging, reducing, testing and annealing plant.

This Shop dells with the repair of all copper and steel pipes for locomotives , also Tin and sheet Metal work for the Northern Division.

This Shop covers an area. of two acres, divided into three bays. On8 bay is required for the repair of tenders, tanks and bogies, and two bays for the repair of engines. Included in the first bay is the cutting out of boiler flue tubes with the 'Wageor' electric machine and 'Feisler' tube cutter.

There are four 50-ton, two 36-ton and two 20-ton electric overhead travelling cranes in this Shop.

Engines entering the Shop are carried to the stripping pits where they are completely dismantled, the parts degreased in an adjacent bosh tank and examined to ascertain the extent of the repairs required. Thereafter the engines pass to the Frame Section, Boiler Section, Assembly Section and Wheeling Section. Material not requiring repair is placed on racks in the Shop and material to be repaired is immediately despatched to the various Shops concerned. After wheeling and valve setting the engine is placed on a seven table weighing machine and the weight on each wheel properly adjusted.

Electric and compressed. air mains are provided throughout for the use of portable boring, drilling and grinding machines. There is also a coal gas main and a main from the liquid oxygen plant with connections at the most convenient points for the oxy-coal-gas burning equipment used at the various stages in the Stripping Section.

The-wheel Shop is served by two 15-ton and one 10-ton electric overhead crane and there is complete equipment for dealing with all types of repairs to locomotive , carriage and. wagon wheels.

A recent addition to this Shop is a Craven horizontal tyre borer. This machine is a high speed tool of the very latest type, designed to use Tungsten carbide tools for the purpose of obtaining smooth finish in the bore. All movements of tool rests are operated by electric motors controlled by press buttons.

In the Wheel Yard there is a 10-ton 199-ft. span electric travelling 'Goliath' crane for handling wheels brought to the Works from Outstations for attention.

The Machine Shop, which is fully equipped with modern machine tools of all types ,deals with all material required for locomotives and carriages.

Experiments with negative rake tools are at present being carried. out on certain machines with a view to reducing the cost of production;

The Tool Room, which is located in the centre of·the Machine Shop and equipped with precision tools, is fitted with special racks for storing small tools, milling cutters, etc.

A card index system. is at present being introduced for the control of all tools in the Shops.

A 'Hilger' Universal Projector has recently been installed for the purpose of checking and measuring gauges, tools etc., employing the system of illuminated optical projection.

All locomotive axleboxes, crossheads, big-end bushes, etc. are machined here and a section of the Shop is allocated for the whitemetalling of components.

The Fitting Shop is divided into sections, each of which deals with definite items such as coupling and connecting rods and motion, brake gear, Westinghouse pumps, etc., and wherever possible is equipped with fixtures for rapid and easy handling of these details. Air operated jib cranes are supplied to facilitate the lifting of these parts.

This Shop is equipped with modern turret and Brassfinishers' lathes, together with necessary benches, jigs and fixtures for dealing with repair of boiler mountings with the least possible handling. A small section of this Shop is allocated for the purpose of testing all pressure gauges.

The Cylinder Section, which is served by a 3-ton electric overhead travelling crane, is equipped with machines laid out for the manufacture of locomotive cylinders on progressive lines from marking off the rough casting to testing the finished cylinder.

In the Welding Shop, which is situated at the foot of No. 3 Bay in the Erecting Shop, there are eight welding booths supplied from an "English Electric" multi-operator A.C. Welding Set. Oxyacetylene welding is carried out in this Shop and recently there has been a considerable development in the amount of cast iron welding work carried out, as the result of experience gained by the welding staff.

The steam hammers range from one to three tons capacity and the furnaces are connected to waste heat boilers which supplement the steam supply.

A number of forging machines and steam hammers are installed in the Smithy on which a considerable variety of work for the C.H.& E.E. and other departments is carried out, and there is a spring making and repairing plant haying thermostatically controlled gas fired furnaces.

The furnaces for the forging machines, etc. are heated by creosote pitch burners, to obviate the use of imported fuel oils. A feature of this installation is the electrically heated pipeline to maintain the requisite viscosity of the fuel.

This Shop deals with tile repairs to all Northern Division horse drawn vehicles. Road motor vehicles are dealt with in a section adjacent to the Carriage Finishing Shop.

All bogie stock for overhauling passes through this Shop at the rate of one vehicle per hour, taking approximately ten hours each to pass through the cycle of progressive repairs to bogies, wheels and underfram.es. After lifting which is carried out with two 15-ton electric overhead cranes, the coaches and bogies are passed through the Shop by continuous moving conveyors along two separate roads, where repairs are dealt with.

Wheel lathes, journal grinder, pipe screwing machine, acetylene and electric welding units and pneumatic tools are provided, also caustic boshes for cleaning bogies and axleboxes.

A separate Shop deals with repairs to vacuum brake components, carriage brass work, internal brass fittings, and. electro- and chromium plating.

The lifting of all short stock is carried out in this Shop, which consists of one road where all vehicles are lifted and the other road is laid out in such a manner that transport is reduced to the minimum and the maximum floor apace is obtained for the actual repairs to the vehicles, and provision made for the material required in the Carriage Lifting Repair Belt. The road is divided into sections equivalent to the maximum number of Vehicles which can be dealt with and each section is divided into bays for the accommodation of reparable items, scrap material and new or repaired components for the vehicle opposite each section.

Due to the large number of repairs now overdue as a result of the war period, this Shop has had to be divided into two sections, i.e. a Body Repair and a Carriage Finishing Section; the former, comprising two roads equipped with working platforms, lies on the right hand side of the Non-Passenger Stock repair line. The Carriage Finishing Section consists of two roads joined by a cross-over along which the carriages are moved in stages where repairs to interior finishings and trimmings are carried out. .A roof dock, re-trimming bay and French polishing section are also provided, as well as a timber component sub-store to reduce transport to a minimum,

The Trimming Shop is situated at the foot of the Carriage Finishing Shop.

Power driven sewing machines, electric cloth cutters and hair carding machines are contained in a separate Machine Shop, as is also a fully equipped Leather Working section for dealing with carriage leather work and leather articles for other departments.

A feature of the layout of the Trimming and Finishing Shops is that the items for repair are removed from vehicles passing out of the Lifting Shop and are repaired in time :for refixing in their respective vehicles as they pass through the final road of the Finishing Shop , thus obviating unnecessary transport.

All Carriage Shops are red by a 70-ft. traverser, on the far side or which is the section fer dealing with all repairs to electric train lighting.

Platform barrows, steam gangways, station seats and furniture is manufactured and repaired here, as well as general joinery for maintenance of Workshop s buildings. Passenger and Goods Station and office furniture is also dealt with.

Equipped with modern machines, the majority of which have individual drives. This section finishes timber for carriage and wagon repairs, furniture and miscellaneous work, as well as for general joinery and building maintenance. Chips and sawdust are removed by exhaust plant and deposited in the Boiler House for steam raising purposes.

The Maintenance Section for circular and band saws, jigs, Gutters and tools has been recently modernised and now includes automatic saw sharpening machines, jig and too1 store and toolroom section for all wood working machines.

This is the main depot for the conversion of logs and trees to scantling for carriage, wagon and road vehicle repairs, Civil and Signal & Telegraph Engineers' timbers.

A hlgh speed horizontal log band saw and a 50-ft. travelling saw beach are capable of dealing with the largest trees. The greatly increased use of home grown timber, caused by the cessation of timber imports, has called for full capacity output from this plant.

Adequate accommodation is provided in these two Shops for dealing with interior and exterior painting of all carriage stock.

Electric current is supplied by Glasgow Corporation at 6,500 volts A.C. to sub-stations at Charles Street

and Springburn Road, where it is transformed and converted to 500 volts D.C. and 440 volts A.C. for machine

tools and cranes and 250 volts A.C. for lighting.

| Consumption for 1944 | Units |

| Power | 3,305,850 |

| Lighting | 1,872,110 |

| Total | 5,177,960 |

| Price per unit | 0.55d. |

| Total cost | £11,799 |

Gas

| Consumption for 1944 |

| 34,300,200 cu.ft. at a cost of &2,895. |

Water

| Consumption for 1944 |

| 59,954,400 galls. at a cost of &3,021. |

Suitable accommodation is arranged for dealing with chain testing and annealing for the Northern Division.

A new 5-ton mobile petrol electric crane now replaces a steam rail crane and facilitates the handling of components up to five tons in various parts of the Workshops.

Transport is provided throughout the Works by means of petrol tractors and trailers.

The necessary air compressor plant, generating equipment for acetylene gas and storage for liquid oxygen are provided.

Gas, high pressure and hydraulic water supplies are obtained direct from the Glasgow Corporation.

An Ambulance Room, equipped for dealing with injuries to male and female employees, is located in a central position.

The Canteen has been in existence for many years and during the war years has been developed to the fullest possible extent. The large hall can seat 450 diners and the Staff Room 80 diners. Approximately 1,100 main meals are served per day, and in addition 1,600 cups of tea.

There is also a Mobile Service which consists of nine trollies which convey tea, biscuits, cake, sandwiches etc ., round the Workshops morning and afternoon, and it is estimated 5,000 cups of tea are dispensed daily together with the eatables mentioned.

The Works Fire Station is situated adjacent to the Carriage Shop and there is a brigade of 33 men including Watchmen. There are three fire alarms in the Workshops connected direct to the National Fire Service which is within three minutes from the Works.

A new two-position telephone switchboard has recently been installed, replacing two Post Office switchboards in the M.&E.E.'s Office and the Stores Dept. and one railway switchboard in the M.& E.E.'s office. The new switchboard combines the two systems and. is connected to the P.O. Exchange by five lines and to the Company's Buchanan Street Exchange by six lines.

During the past year the following modern machines have been installed, replacing life-expired machine

tools:-

2 Combination Turret Lathes

4 Hexagon Turret Lathes

2 18" Shaping Machines

2 5' 0" Radial Drilling Machines

1 Two-spindle Sensitive Drilling Machine.

1 3'6" Radial Drilling Machine

1 4' 6 " Radial Drilling Machine

1 Vertical Milling Machine,

and the following replacements are on order :-

1 Punching and Shearing Machine

2 36" Vertical Boring and Turning Mills

1 Combination Turret Lathe

1 No. 4 Capstan Lathe

1 Brassfinishers' Lathe , 8½"

1 Tool and Cutter Grinding Machine.

Moulding Machine.

The plant has also been augmented by the installation of :-

1 'Hilger' Universal Projector

1 Wheelabrator Shot Blast Machine

1 High Speed Router

3 Saw Sharpening Machines.

New office accommodation for Production Planning Section.

Extension of Boiler Shop for continuous repair layout.

New shop for repairs to road vehicles.

Conversion of present Road Vehicle Repair Shop for heavy repairs only to carriage underframes and damaged

carriages, also sub-store for Lifting and Underframe Shops.

Centralisation of steam supplies.

Reorganisation of Forge.

Provision for cleaning locomotive underframes by steam.

Road bridge to Iron Foundary.

Replacement of exhausting plant, Wood Machine Shop.

Extension of Varnish Shop. Provision of additional 500 K.V.A. transformer, etc.

Provision of L.T.A.C. distribution system throughout the Shops.

etc. etc.

Site contents Copyright © LMS Society, 2026

February 2nd, 2026

Site contents Copyright © LMS Society, 2026