This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

[as described in the July 1934 edition of the “in-house” LMS Magazine.]

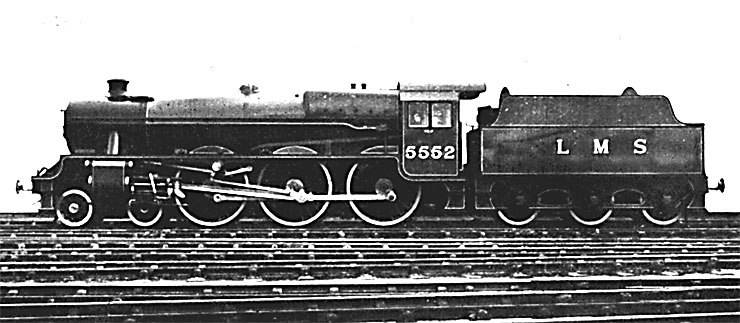

ONE hundred and thirteen new three-cylinder 4-6-0 superheated passenger tender engines are being built this year to the designs of the Chief Mechanical Engineer. They will be numbered 5552 to 5664. The photograph and diagram show the general appearance and overall dimensions of these engines the first one of which, No. 5552, was built at Crewe Works.

This locomotive has the same wheel arrangement as the rebuilt three-cylinder "Claughton's" with parallel boilers, a number of which have been converted at Crewe and Derby, and are now well known as the 5X Class.

A tapered type of boiler barrel has been provided and the working pressure is 225 lbs. per square inch.

A superheater is fitted and the main regulator has been incorporated in the superheater header in the smoke box. A steam manifold (with a main shut-off valve) is provided on the top of the firebox doorplate in the cab, on which are provided the necessary valves for: ejector and steam brake; injectors; carriage warming; whistle; pressure gauge; sight feed lubricator to regulator.

The feed water is supplied through top-feed valves on the second boiler barrel ring with water distributing trays. Two pop-type safety valves (2½ in. dia.) are fitted at the crown of the firebox.

An exhaust steam injector (11 mm. cones) is fitted on the fireman's side, and on the other side is fitted a live steam injector (11 mm. cones). Other boiler mountings, such as the water gauge frames and protectors, etc., are of the Company's standard type.

The three cylinders are 17 in. diameter by 26 in. stroke, whilst the three sets of motion are of the "Walschaert" type, a travel of 6⅜ in. being provided for the outside cylinders and 6k in. for that inside. Piston valves, cylinders and piston rod packings are mechanically lubricated. (The lubrication for each piston valve head is provided with a steam atomizer) ; the valve spindle bushes have also mechanical lubrication. The mechanical lubricators are the Company's standard type.

The coupling and connecting rods and motion, in accordance with the latest practice, are of high tensile manganese molybdenum steel, the connecting rods being of a fluted section and the coupling rods of rectangular section.

Wheel centres are steel castings with the wheel rim of triangular section and the tyre fixing is of the "Gibson" retaining ring type. The balance weights for the coupled wheels are built up by steel plates on both sides of the spokes, and riveted, the requisite weight being provided by filling in between the plates with lead.

The axleboxes for coupled wheels are steel castings with pressed-in brasses with suitable white metal crown and oil grooves provided on both sides of the crown to ensure a thorough distribution of oil to the journal. The axle box under keep carries an efficient oilpad.

The middle and trailing axleboxes are arranged so that the oilpads can be examined by sliding out the underkeep while the axlebox is in position. This arrangement, however, cannot be provided on the leading coupled axleboxes on account of the crank axle and eccentrics. Each of the axleboxes is provided with a dust shield carried on the inside face of the box.

A separate mechanical lubricator supplies the coupled axle boxes, each of which has an independent oil feed to the crown of the box, with the standard back pressure valve and flexible oil pipe connection.

All the laminated bearing springs for the engine and tender are made of silico manganese steel, the plates being of a ribbed section, and with the cotter type fixing in the buckle. The spring links are of the screwed adjustable type.

The four-wheeled bogie is the standard type, the weight being taken through side bolsters, and the bogie side check spring gear is provided to ensure smooth riding.

The width over the cab is 8 ft. 6 in. All controls are arranged for convenient handling and tip-up seats are fitted on each side of the cab. Two sliding windows are fitted on each side and hinged windows on the cab front plate. A small hinged window is provided on each side to act as a draught preventer for the enginemen when looking out.

Steam brake is provided on each of the coupled wheels and operated by the driver's vacuum brake valve. A vacuum pump driven from the crosshead is fitted on the left-hand side of the engine.

The sanding is of the mechanical trickle type, the sand being delivered to front of leading coupled wheels, or front and back of middle coupled wheels.

In addition to this a water de-sanding apparatus is provided which automatically cleans the rails with hot water after the sand has been used. to prevent interference with the track circuits.

The tenders of engines Nos. 5552-5556 and 5607 to 5664 are of the 6-wheeled type of 13ft. wheel base with a water capacity of 3,500 gallons and with accommodation for 7 tons of coal.

Those of engines Nos. 5557-5606 are also of the 6-wheeled type but with a wheel base of 15ft. and a capacity of 4,000 gallons of water and 9 tons of coal.

Both types are provided with a bunker door giving access to the coal space from the footplate and there is ample toolbox space on the front of the tenders.

The necessary firing irons are housed in a suitable cavity on the left-hand side of the tender.

The water pick-up and tender hand brake handles are arranged vertically.

A steam brake is provided on each of the six tender wheels and is applied simultaneously with the steam brake on the engine.

As a further means of obtaining a smooth-riding locomotive, the intermediate drawgear has been carefully designed with buffing spindles controlled by coiled springs.

The buffing spindles have a specially designed head which rides on inclined planes, provided on the hind engine buffer beam.

Site contents Copyright © LMS Society, 2025

December 1st, 2025

Site contents Copyright © LMS Society, 2025