This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

[as described in the October 1925 edition of the “in-house” LMS Magazine.]

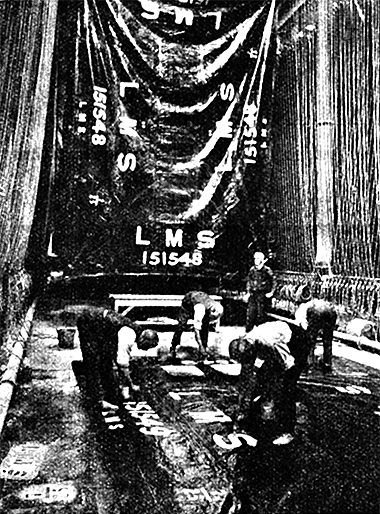

Stencilling Wagon Sheets

THE original building at Trent was erected as a coke store alongside the basin or the Erewash Canal, the sheet shop being ther at Derby. Growth of the Midland Railway necessitated larger premises, and Trent being geographically the centre of the system, an ideal point for distribution was chosen in 1848 The staff numbered 20, including sailmakers who performed part of the work, namely, the sewing of the sheets, in their own homes. The Midland ball, a function of social importance was held in the Repairing Shop about 1860. The elaborate decorations always connected with this event converted a drab sheet shop into a resplendent ballroom. Special trains from Derby brought the parties into the sidings, where a temporary platform was erected. The mess room was converted into a supper room. Later the ball was transferred to Derby Royal Drill Hall, where it continued its successful course until the formation of the L M S Group.

There is neither town nor village of Trent, which is solely an important junction station, close to the town of Long Eaton and village of Sawley.

The principal work is the manufacture of wagon and dray sheets. These are made from grey can vas of English or Scotch weaving, some sheet makers preferring the dry spun yarn and others the wet. The canvas is made in bales of about 100 yds., chiefly 36 or 42 in. wide, and varies in weight from 16 to 12 oz. per square yard. For a wagon sheet five breadths are sewn together by power-driven machines, which place a double row of stitches in the seams and a single row in the "tabling." During the sewing, strengthening tabs are inserted for the eyelet holes, into which before issue are knotted the cords for fastening down to wagon sides. An ingenious invention by the Works Engineer is used for punching holes in the tabs at the rate of 60 per minute. A grummet machine sews an iron ring into the tab with a needle which runs round the ring in a similar manner to buttonholing.

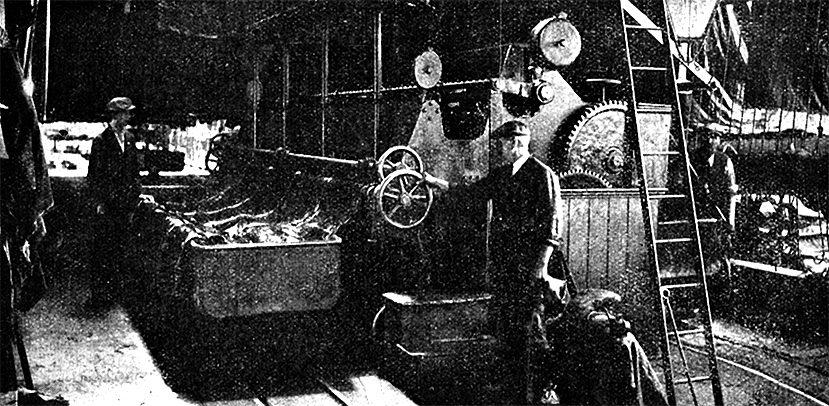

Sheets Passing Through Dressing Machine

From the machine shop the sheets are run on a trolley-way into the "dressing" shop. The grey sheets are unfolded, strung together, and passed in a continuous line through the dressing machine. This machine, one of the first to be installed, receives the sheets on long rollers, over and under which the sheet passes. A swinging arm fitted with brushes receives the dressing composition from a roller which revolves in a trough fed by pipes from a tank, and brushes the liquid into the canvas. The brushes pass three times over each section of canvas, while at the back of the machine "dressers" dab the seams with a thick dress, which ensures an extra covering of the vital parts with waterproofing mixture. Whilst this is being done an arm of the machine folds the wet sheets into a container or tank, running on trolley lines. When full, the attachment cords are cut and the container is run down to the hanging bays. Here the sheets are hauled up on halyards to dry, after which they are again passed through the machine. This operation is repeated until each side of the sheet has been dressed three times.

The next operation is painting. The sheets are lowered off the halyards, lettered and numbered. Prior to the grouping each railway had its own distinctive marking, in addition to the initial letters. The Midland had an orange border; the L. & N.W. a red cross, and the L. & Y. red and white stripes. The N.S. used the Staffordshire knot, and the Cal. a blue cross Now, however, all the group sheets are standardised and bear no other identification marks than the initial letters L M S and number The month and year of issue is shown in two corners, while the opposite corners are post-dated, indicating the date the sheet should be sent into depot for redressing. The standard sheet measures 21 ft. by 14 ft. 4 in. After painting and stringing (the latter operation consisting of knotting 16 manila cords, tar dipped, through the ringholes), the sheets an again hauled up for the paint to dry until required for traffic. Before being folded the sheets are either sprinkled with sand, sawdust or soapstone (the latter being the present method) to prevent their sticking in transit. A further precaution against this trouble is the loading of the sheets "on end" and not flat in the wagons.

The mixing of the tarpaulin dress, which, by the way, does not contain tar, is an interesting process. Oil is emptied from barrels into a large pit, the capacity of which is 2,830 gallons. It is then pumped into mixing tanks, where the necessary ingredients are added and fan-like "beaters" revolve to mix the component parts. The mixture is next pumped through pipes to the dressing-machine feed troughs mentioned above. The Brunswick green dressing for dray sheets is mixed in an auxiliary tank and then conducted to the machine.

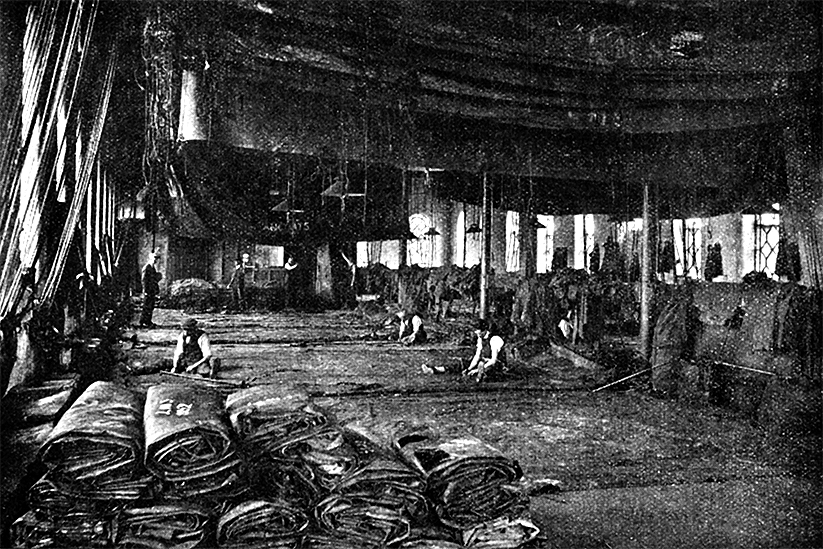

Owing to the size of the "dressing" shop a ventilating plant is used to provide a current of either cold air or dry warm air; according to the prevailing atmospherical conditions. The air is conducted along the bays and forced down large cylindrical shafts, thus securing an even temperature. This shop has hanging space for over 2,500 sheets, in addition to miscellaneous articles. Over 34 miles of hemp rope halyards are needed for this purpose. Trolley lines connect with an auxiliary drying shop and other parts of the works.

The average life of a wagon sheet is about five years, which, considering the rough usage, fair and unfair, is a remarkable tribute to the efficient manufacture and skilled attention given by the various group depots in redressing and repairing.

All classes of ropes and miscellaneous canvas articles are manufactured at Trent, which is also the depot for rope rings and chain trestles.

Sheet Repairing

Site contents Copyright © LMS Society, 2026

February 15th, 2026

Site contents Copyright © LMS Society, 2026